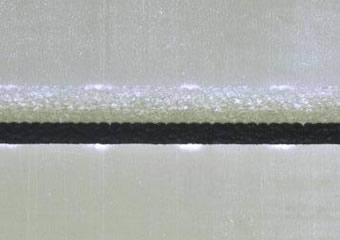

The situation that the roughness of cutting surface does not meet with the quality target, or the roughness become worse unusually because of trouble.

Rough cutting surface

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Small rake angle. | If the cutting edge is not sharp, the roughness of cutting surface becomes worse. | Use the router with large rake angle. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Fast feed rate. | If the feed rate is too fast, the force act on the board increases. It is easy to damage the boards. | Reduce feed rate. |

| High spindle speed. | Too high spindle speed causes vibration of the router. It causes rough cutting surface. | Reduce spindle speed. |

| High spindle speed, slow feed rate. | The condition hastens the cutting edge wear. The dull cutting edge causes rough surface. | Reduce spindle speed and increase feed rate (unless breakage is not happened). |

| Route in the direction of down cut. | For the roughness of the cutting surface, down cut surface may be worse than up cut surface. | Route in the direction of up cut. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Moving the boards. | If fixed inadequately, boards may move and become an unstable routing. | Fix the boards to the work table rigidly (check the stud pins and the fix tape). |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Large spindle runout. | The rotation of the router becomes unstable. | Repair the spindle (collet). |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill