The situation that dimensional accuracy does not meet with the quality target, or the accuracy

become worse unusually

because of trouble.

The dimensional accuracy is checked by calliper, micrometer, measuring mircoscope, coordinate

measuring machine, etc.

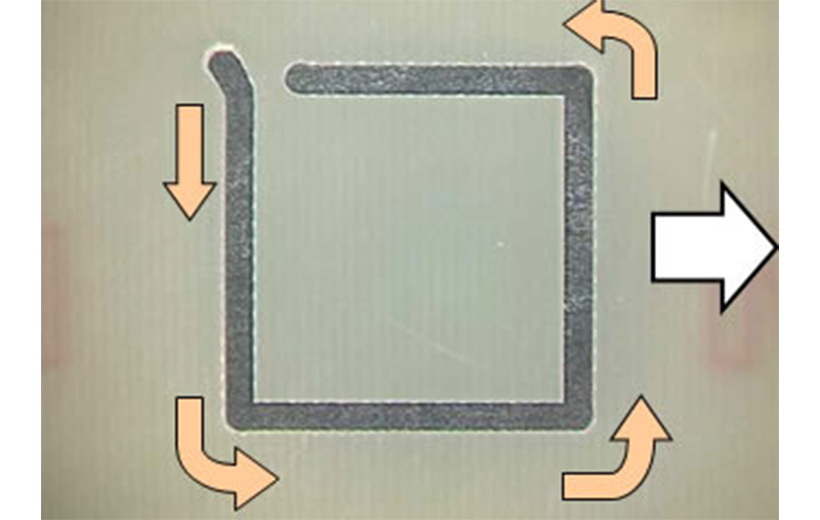

Routed out a piece

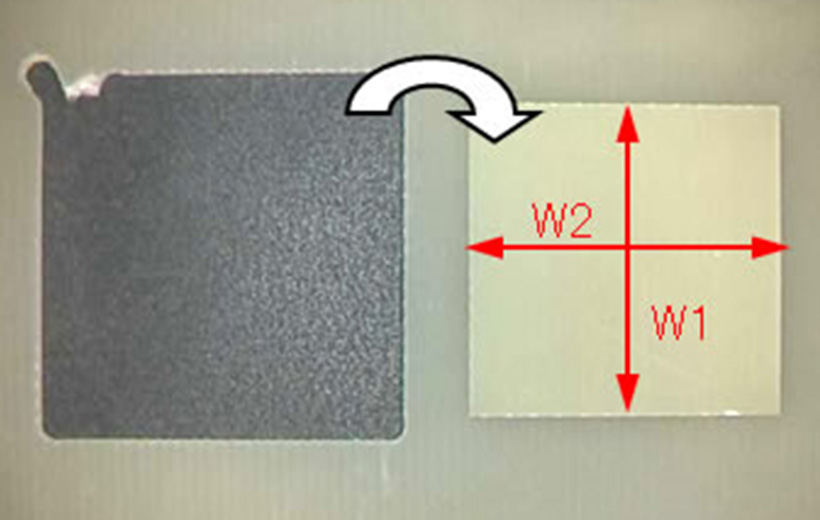

Measure a piece

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Poor router bit strength. | Dimensional accuracy becomes worse because of large deflection of router. | Change router geometry (web thickness / flute depth, web taper). |

| Long flute length. | If flute length is unnecessarily long, bend and dimensional inaccuracy happen easily. | Decide flute length suitable for the stack heights of boards. |

| Increase the penetration depth into backup board to use near the flute end of the router. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Fast feed rate. | If the redial load on the router increases, it is easy to bend and dimensional accuracy becomes worse. | Reduce feed rate. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Moving the boards. | If fixed inadequately, boards move easily and dimensional accuracy becomes worse. | Fix the boards on the work table rigidly (check the stud pins and the fix tape). |

| Stack height of the boards is too high. | If the stack height increases, router bends easily and dimensional accuracy becomes worse. | Reduce stack height to satisfy the quality target. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Large spindle runout. | If dynamic runout increases, dimensional accuracy becomes worse. | Repair the spindle (collet). |

| Trouble of the work table. | If the motion of ball screw and guide rail is not smooth, dimensional accuracy becomes worse. | Maintain the work table. |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill