A very hard coating is formed by the diamond structure.

This hard and anti-wear coating shows good routing performance on

very hard materials.

With Diamond-coated routers, it is possible to enhance tool-life and

rout those difficult-to-machine materials that were impossible with

conventional routers.

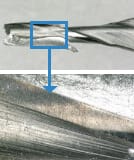

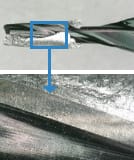

| Work | AC-7302(2W/mk) t1.5mm(Non copper,100μm/Insulating layer,1.5mm/Aluminum plate) x 1 panel/strack |

|---|---|

| Conditions | N = 30krpm, Fxy = 0.6m/min, f = 20μm/rev, Fz = 0.1m/min, DIB = 1.0mm |

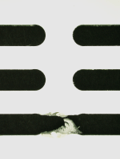

Non-coat

(After 1m)

ULF coated

(After 1m)

New Diamond coated

(After 20m)

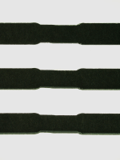

Non-coat

(After 1m)

ULF coated

(After 1m)

New Diamond coated

(After 20m)

Diamond coated router "DCRSE" has good performance for Aluminum

4000 series which is often used for Aluminum base panels in

recent years.

Optimized coating and high-quality 2 flute/left-hand

(down-draft) design achieve controlling burr and smooth surface.

To inquire for the detail, please click on "CONTACT" button

below.

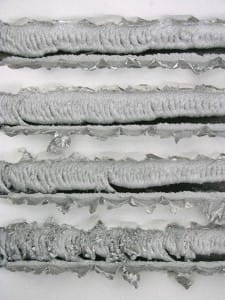

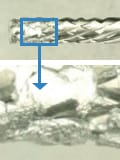

Panel Appearance

Conventional

Diamond-cut

Conventional

2 flute

New

DCRSE

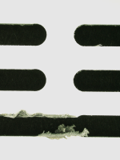

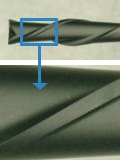

Router Appearance (φ2.0)

Conventional

Diamond-cut

Conventional

2 flute

New

DCRSE

Material:A4045 Aluminum core panel t1.5mm

Routing Condition:N 30krpm、 F 0.6m/min

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill