The situation that board surface or edge is not smooth because of irregular routing.

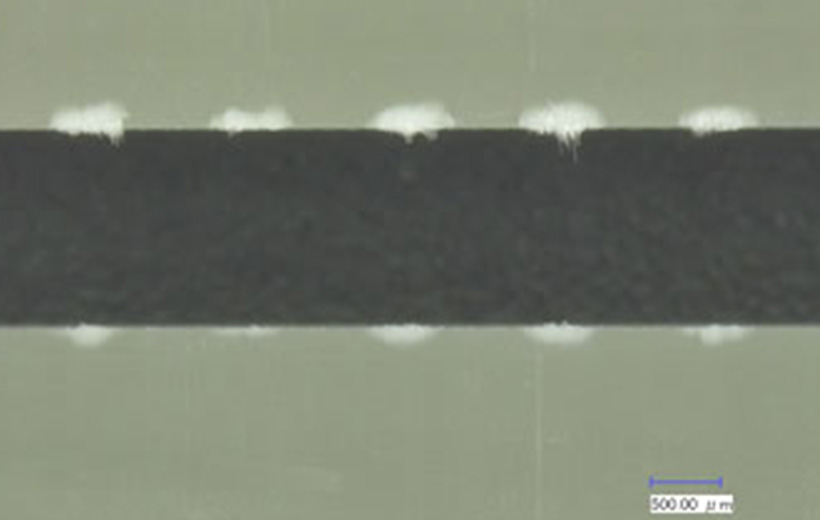

There are "copper burr", "glass

cloth burr", "resin burr", etc.

Copper burr

Glass cloth burr

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Large thrust force. | Too large upward force acting on the board causes burr on the surface of the board. | Use entry board. |

| Use a router with small helix angle. | ||

| Use a router which has left hand, down draft geometry. | ||

| Heavy wear. | When the wear is increased, the cutting edges lose their sharpness and burr occurs on the board. | Change to the new router. |

| Reduce spindle speed and increase feed rate (unless breakage is not happened). |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Fast feed rate. | Fast feed rate causes large force lifting up the boards, and burr occurs easily. | Reduce feed rate. |

| High spindle speed, slow feed rate. | This condition hastens the cutting edge wear. In this situation burr occurs easily by the dull cutting edge. | Reduce spindle speed and increase feed rate (unless breakage is not happened). |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Board material, composition. | Because of the hardness of board or adhesional strength of layer, there are some materials that burr occurs easily. | Use entry board. If necessary, add the finish routing. |

| Opening between the stack of the boards. | If there is opening between the two boards, burr occurs to the space easily. | Set the boards on the work table firmly not to make the opening between the boards (check the stud pins). |

| Moving of the boards. | If fixed inadequately, boards may move and become some opening between the boards. In this case, burr occurs to the space easily. | Fix the boards on the work table rigidly (check the stud pins and the fix tape). |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Large spindle runout. | The rotation of the router becomes unstable and burr occurs easily. | Repair the spindle (collet). |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill