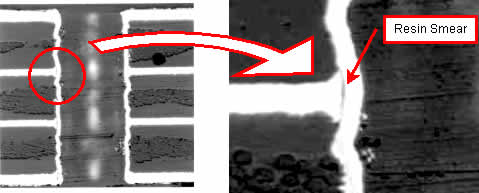

Resin is melted by the drilling heat, and attaches to the inner or outer copper layers.

| Cause | Failure condition | Countermeasure |

|---|---|---|

| ST Type | Increased area of contact between the drill bit surface and hole wall raises drilling temperature. | UC type |

| Large margin width | Increased area of contact between the drill bit surface and the hole wall raises drilling temperature. | Select suitable margin length. |

| Small chip pocket | Low swarf evacuation causes the resin to attach to the inner copper layers in the hole wall. | Smaller chip pocket |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Repointed drill bit which has excessive diameter wearing at the drill tip. | Increased drilling temperature causes smear. | Check wearing condition. Repointing must remove correct amount to return full diameter. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Low chipload and hit count to high | Low chipload promotes wearing, and causes smear. | Higher chipload |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Low glass transition temperature (Tg) | If the drilling temperature approaches or exceeds Tg, causes smear. | Use Hi-Tg material. |

| Hinge number and thickness of PCB copper layers | High cutting resistance increases drilling temperature, causing smear. | Decrease PCB stack heights and hit count to reduce drill bit damage. Use double drilling method. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Non desmearing | Remaining smear. | Desmear treatment |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill