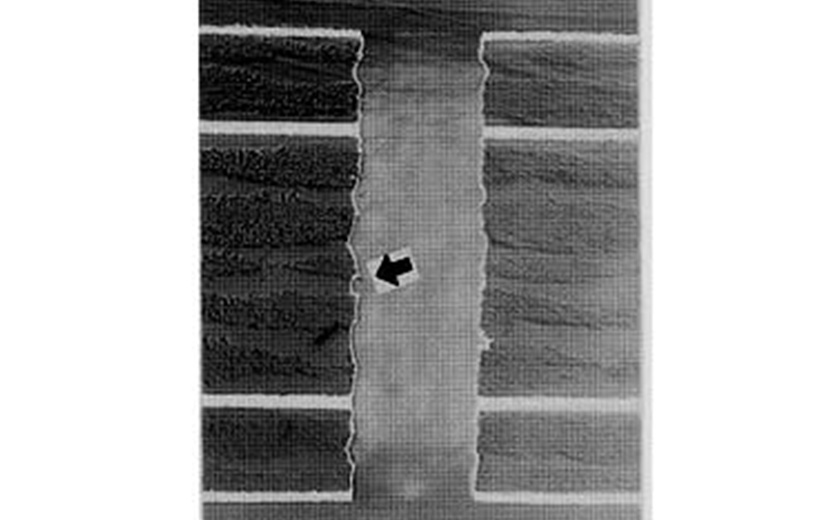

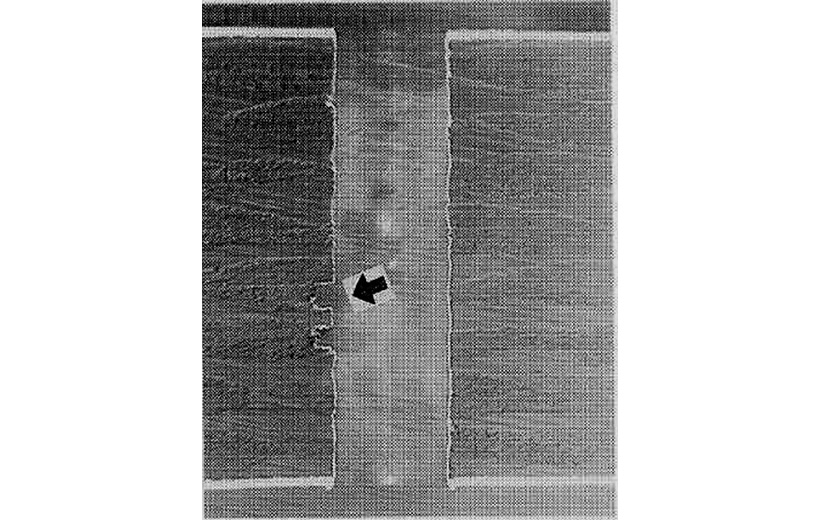

The photographs below show some very rough holes caused by drilling.

This defect should be controlled to satisfy the quality demanded.

Gouged resin part

"Tear-Out" glass cloth part

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Small chip pocket (flute volume) | Chip clogging causes increased roughness. | Enlarge chip pocket volume, change web thickness web taper, and flute land ratio. |

| Short flute length and body length | If swarf clogging occurring at the end of flute, it causes a rough finish. | Set suitable flute length for stack height. |

| Unsuitable drill bit geometries (helix angle) | A drill bit with a low helix angle (30-36 deg.) does not evacuate swarf smoothly, causing roughness | Higher helix angle (40 - 45deg.) |

| Large margin length | Increased area of contact between the drill bit surface and the hole wall raises drilling temperature causing roughness. | Smaller margin width. |

| Unsuitable tungsten carbide material | Increased wearing blunts the drill's cutting edges, causing roughens | Use wear-resistant WC material. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Excessive repointing amount | Reduced flute volume causes swarf clogging and roughness of hole wall | Control amount removed of material at repoint (0.05-0.10mm). Check overall length of repoint drill bit. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| High chipload | High chipload drilling increases the volume of chips, making it hard to evacuate, causing a rough finish. It is also possible that a damaged cutting edge can influence roughness of hole wall. | Apply suitable chipload. (Please refer to drilling parameters.) |

| Low chipload | Low chipload promotes wearing, and causes a rough finish. | |

| Unsuitable pec drilling | If the number of steps and the amount of feed don't match the PCB setup, it worsens swarf evacuation and causes a rough finish. | Recalculate pec drilling step increments/parameters |

| Penetrating to deep into the backup board | Materials such as Backing Board generate large particles of swarf which can adhere to the drill causing Bird Nesting. | Apply suitable penetration depth. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Panel stack height to high | Large volume of chips causes Swarf clogging | Lower chipload. Decrease PCB stack height. |

| Hinge number and thickness of PCB copper layers | Spiral Copper chip form blocks chip evacuation and high copper content causes wearing. | Lower chipload. Use a type which has enough chip pocket to promote good roughness of hole wall |

| Thick and few layers PCB (Example t1.6, D/S) | Likely to have grubbed and rough finish. | Lower chipload. Use a type which has enough chip pocket to promote good roughness of hole wall |

| Hard cutting PCB material | The increase of cutting resistance causes wear and worsens accuracy. | Decrease PCB stack heights and reduce hit count to minimize drill bit damage. |

| Unsuitable entry board | Using aluminum entry board, fine roughness of hole wall can not always be expected. The lubricant type offers better comparability for fine hole wall condition | Use high quality entry board like attached water soluble resin type, multi-layer aluminum type, etc. |

| Unsuitable Stack preparation | A gap between the entry board and PCB causes poor chip evacuation. | Prepare stack with no gaps between entry board and PCB |

| PCB qualities | Uneven resin and fiber intersections worsen roughness of hole wall | Check PCB quality. Example: Check unevenness of PCB using an image processor/AOI machine for measuring hole positioning accuracy. ---> An extreme striped pattern, etc. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Unsuitable Vacuum force | Low vacuum force worsens chip evacuation, and causes rough hole wall. | Set suitable vacuum force. (Recommended value: 0.4dia. 100-150 hPa, 0.1dia. 70-140 hPa) Maintain dust catcher system of the drilling machine. |

| Unsuitable force of pressure foot | A wider inner bush cause poor chip evacuation and roughness of hole wall. | Using small inner diameter bush. Example: Change from 10mm to 3mm inner dia. |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill