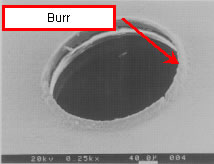

Burr occurs around drilled holes as shown in the right hand picture.

This "Troubleshooting" guide explains about burr, especially on the front of the PCB.

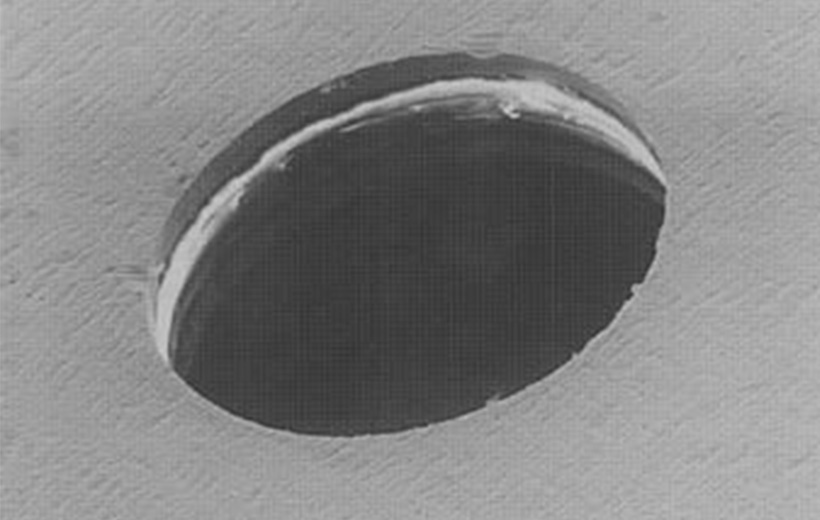

Normal Hole

Hole with burr

| Cause | Failure condition | Countermeasure |

|---|---|---|

| High chipload | Increase of thrust force causes burr. | Apply suitable chipload. (Please refer to drilling parameters.) |

| Low chipload | Low chipload promotes wearing, and it causes burr. | |

| Hit count to high | Too many hits promotes wearing and causes burr. | Apply suitable Hit Count |

| Raised entry board | Burr occurs on the front of the PCB. | Check entry board setting. Use thicker entry board. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Unsuitable entry board | Thinner PCB's are less rigid and more likely to "ride-up" the drill, causing burr. This also applies to soft / flexible materials | Using suitable thickness entry board. |

| Cause | Failure condition | Countermeasure |

|---|---|---|

| Unsuitable bush and pressure foot setting | A deformed bush can't press entry board properly. A worn pressure foot bush makes uneven contact. | Change bush. Checking pressure foot. |

| Low pressure foot pressure | PCB lifts more easily causing burr. | Set correct pressure foot force. (Recommend: About 100-150 N, Suitable value is depends on application) |

| Non deburring | Untouched burr. | Deburring |

PRODUCT 01 PCB Drills / Routers / Ultra precision micro-hole drill