3mm shank with h4 tolerance x overall length 38※mm long neck short shank series.

We have applied mass production technology for 30 million PCB tools per month to end mills to achieve a more affordable price.

Achieves high precision and high efficiency machining with equipment specialized for high precision machining of small diameters.

Ideal for deep rib processing of die & mold materials and copper tungsten to high hardness materials.

Compatible with shrink fit holders as well.

(※The overall length of VCBN series is 35 mm)

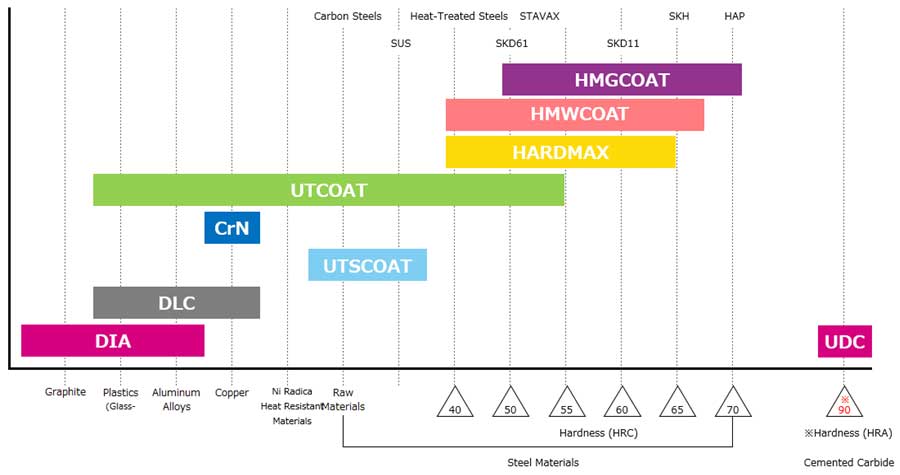

| Copper, Aluminum | Raw Materials ~ 55HRC | >Hard Materials (40~65 HRC) |

Hard Materials (50~70 HRC) |

||

|---|---|---|---|---|---|

| Square | |||||

| Long Neck Square |

|||||

| Long Neck Radius |

|||||

| Ball | |||||

| Long Neck Ball |

HMGCOAT offers the highest wear resistance when milling hard materials.

Long life milling in hardened steel, especially 60HRC and above.

| Square | Ball | Long Neck Ball |

Long Neck Radius |

|

|---|---|---|---|---|

| 2 Flutes | - | - | ||

| 4 Flutes | - | - | - | |

| 5 Flutes | - | - | - | |

| 6 Flutes | - | - |

HARDMAX coating achieves both hardness and heat resistance that is essential for milling hard

materials.

This series demonstrates its performance especially when milling hard materials of 40HRC and above.

New coating HMWCOAT, with improved wear resistance compared to

HARDMAX coating. Improved wear resistance for prehardened steels to

65HRC hardened steels.

This series provides excellent performance in hard materials around 60HRC.

UTCOAT offers high lubricity and toughness.

Smooth surface, low coefficient of friction, and high chip evacuation and wear resistance.

This series is suitable for raw materials and tough materials.

| Square | Long Neck Square |

Ball | Long Neck Ball |

Radius | Long Neck Radius |

Taper | |

|---|---|---|---|---|---|---|---|

| 2 Flutes | - | ||||||

| 3 Flutes | - | - | - | - | - | ||

| 4 Flutes | - | - | |||||

| 5 Flutes | - | - | - | - | - |

New coating UTWCOAT, with higher toughness and improved wear resistance

resistance compared to conventional UTCOAT.

This series provides excellent performance for raw materials up to 40HRC.

UDC is a special diamond coating that adds toughness to its outstanding hardness.

Obtains incredible cutting performance with cemented carbide and hard brittle materials by improving

the adhesion

between the carbide grade and diamond coating.

Achieves high-precision and high-quality finishing for cemented carbides and hard brittle materials, by using a binderless PCD with extremely high wear resistance to form a very sharp cutting edge.

CBN material is suitable and optimized for ultra-hard materials is, and the cutting edge geometry

ensures that a high

quality and high precision surface finishing can be achieved.

Stable milling of hard materials of 40HRC or harder throughout its long cycle time as compared to

other coated carbide

tools.

Diamond coating offers high adhesion and improved wear-resistance.

Long tool life when milling graphite.

CrN and DLC COAT offer high levels of lubricity.

DLC COAT uses proprietary technology to further improve hardness and lubricity, and offers high

quality and longer tool

life with copper and copper tungstate electrodes.

UTSCOAT improve the resistance to adhesion by adding a highly lubricant layer onto the UTCOAT that

already benefits

from high lubricity and toughness.

Excellent performance for milling tough materials, especially stainless steels.

Designed especially for Aluminum milling with excellent sharpness and outstanding chip

evacuation.

Improving hardness and lubricity of DLC with proprietary technology offers longer tool life.

※CAS and AZS are NON-COAT Series.

Among UTCOAT series designed for tough materials, this series has the optimum cutting edge geometry especially for difficult-to-cut materials.

Designed especially for Plastic milling with excellent sharpness, such as long neck and long overall length models.