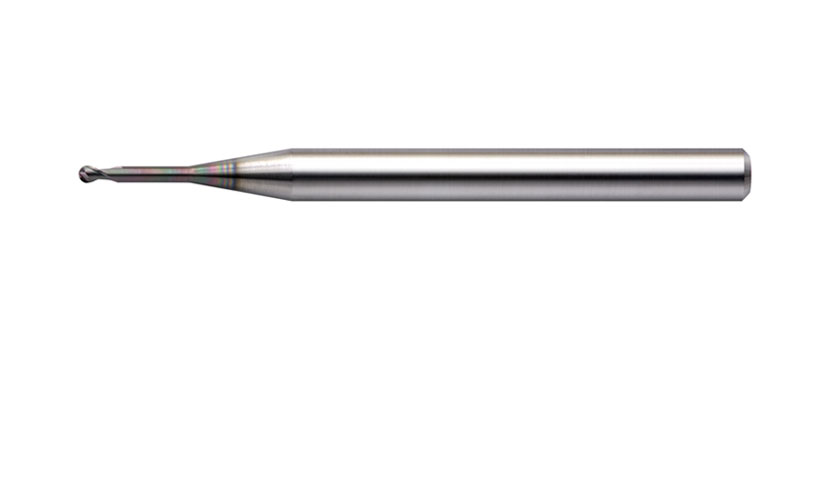

3mm shank with h4 tolerance x overall length 38mm long neck short shank series.

We have applied mass production technology for 30 million PCB tools per month to end mills to

achieve a more affordable price.

Achieves high precision and high efficiency machining with equipment specialized for high precision

machining of small diameters.

Ideal for deep rib processing of die & mold materials and copper tungsten to high hardness

materials.

Compatible with shrink fit holders.

Utilizing the production know-how of PCB drills for electronic circuit board drilling,

Small-diameter carbide end mill "V series" with affordable price.

A new lineup of 2-flute long neck radius type for high hardness materials up to 70HRC has

added!

Optimized flute edge geometry with improved wear and chipping resistance realizes long tool life

and high precision milling.

A wide variety of variations specialized for small diameter processing are being developed one

after another!

HMGCOAT long neck ball is a new offering for the V series.

Offers higher wear resistance compared to HARDMAX, and is suited for hardened steels and high

speed steels over 60HRC. It is very effective for high-performance and high-quality milling of

high-hardness materials. It can be used in shrink fit holders.

Vertical milling directly achieves shorter processing time by removing pre-drilling or ramping

cycle!

DLC COAT offers excellent resistance to wear and welding.

The flute shape is specifically designed for reducing burrs on Aluminum Alloys.

New lineup of long neck square VDLCLS for copper and aluminum!

Sharp cutting edge reduces burrs on milling surface

DLC coating offers excellent welding and wear resistance.

DLCCOAT 2 Flute Short Shank Type Long Neck Ball End mills VDLCLB.

New release of Long Neck Ball End mills for copper electrode Milling with V series Achieves

excellent welding and wearing resistance resulting from the DLC coating.Achieves an

unprecedented tool life with a special flute design for milling copper and aluminum.

Also compatible with shrink fit type holders.

Utilizing the production know-how of PCB drills for electronic circuit board drilling,

Small-diameter carbide end mill "V series" with affordable price.

A new lineup of 2-flute/4-flute square types have added!

A wide variety of variations specialized for small diameter processing are being developed one

after another!

UTCOAT long neck ball is a new offering for the V series.

Offers high toughness and lubricity, and suited for a wide application range from copper/raw

materials up to 55 HRC.

It can be used in shrink fit holders.

The first V series lineup.

HARDMAX coating that achieves both hardness and heat resistance and well suited for hard

materials over 40 HRC.

From Copper-Tungsten mold material to high hardness materials, it offers high performance and

high quality milling.

These models can be used in shrink fit holders.

Now, high-toughness carbide can also be milled with UDC.Reduce the damage during

milling due to the angled flute design. UDC coat’s outstanding adhesion to the tool

allows milling of tough materials.Highly improved material removal volume when milling 87HRA or lower hardness of cemented carbide material.

Newly released UDCRRS multi-flute radius end mills from our UDC series for milling cemented

carbide. The 6 to 10 flutes and the 40 degree helix angle achieves low cutting resistance and

offers deep cutting depth milling!Compared to the 2 flute models, the efficiency has been

dramatically increased!

This contributes to the reduction in cycle time.

High efficiency and long life Ball End Mills for milling cemented carbide.

High-level treatment to reduce cutting resistance and mill at a high feed rate.

Wear resistance improved drastically with optimized diamond coating

Best for roughing and semi-finishing.

Long life Long Neck Ball End Mills for milling Cemented Carbide.

High-level treatment to reduce cutting resistance and minimize damage on cutting edge. Wear

resistance improved drastically with optimized diamond coating. Best for roughing and

semi-finishing.

Long neck radius has been added to the UDC-H series!

The new generation cutting edge treatment enables amazingly high feed rates on cemented

carbide.

This series is ideal for roughing to semi-finishing. By replacing EDM processing with machining,

manufacturing lead time can be significantly shortened!

HMGCOAT with improved wear resistance provides excellent performance in hard work materials over 60HRC. 6 flute design is applied to all sizes. Diameter tolerances have been significantly tightened compared to the conventional models. Optimized cutting flute design enables high accuracy milling and near right angle corner milling.

A multi-flute long neck radius end mill with HMG coating is now available!

The multi-flute design and high rigidity due to the short flute length allows for stable milling

even under extremely high efficiency conditions!In addition, in order to support high-precision

milling, each tolerance has improved.

4 flute long neck radius series with HMG coating.

By adopting a strong negative rake angle, an extended tool life is achieved especially when

milling high hardened materials of 60 to 70 HRC. The milling accuracy and surface quality are

greatly improved!

New coating HMWCOAT, with improved wear resistance compared to HARDMAX coating. Negative cutting flute design and new coating provide excellent performance in hard materials around 60HRC. Improved tool accuracy compared to previous models(HSB/HSB-S). We also have short shank series. Compatible with high accuracy shrink-fit-holder, minimizes overhang length, achieving higher accuracy milling.

Newly developed long neck ball with HMW coating is now available!Improved wear resistance from

prehardened steels to 65HRC hardened steels.

In addition, we achieve very high accuracy with an outside diameter tolerance of 0/-0.006, and R

accuracy of ± 0.003.

New coating UTWCOAT, with improved wear resistance compared to UTCOAT. New coating and micro flatland design provide longer tool life and improved mirror surface finish on SCM Prehardened Steels. Improved tool accuracy compared to previous models (CSEB).

We have developed a new coating named UTWCOAT, which has higher toughness and improved wear

resistance than conventional UTCOAT.

New coating and a micro-flatland design at the tip improves long tool life and specularity

especially for SCM-based pre-hardened steel.

UTCOAT achieves long tool life in machining low to medium hardness materials, from raw materials up to 40 HRC.Reduces tool marks and improved mirror surface finish for flat milling.Improved diameter tolerance, radius accuracy, and shank diameter tolerance enable even higher precision milling.

Tool design for highly efficient and stable milling.

Minute clearance surface on the peripheral cutting edge

suppresses chatter and realizes outstanding milling stability.

Improved chip evacuation by combining the unequal segmented

angle adjustment and the conventional unique groove

shape. Enables higher feed rate and shorter milling time than

conventional tools.

Optimized CBN material for milling of ultra-hard materials, with excellent wear resistance offers long tool life. Our unique tip design maximizes burnishing effect to enable super mirror milling. CBN long neck ball with an improved surface finish compared to conventional tools. Shank diameter tolerance, 0/-0.004 mm. Ball radius accuracy ±0.002 mm.

Optimized CBN material for milling of ultra-hard materials along with the improved cutting edge

geometry allows for high precision milling and long tool life.

Excellent wear and chipping resistance ensures an outstanding surface roughness and precision

throughout the long cycle time. 4 flute shape withstands high efficiency milling.

Milling time can be significantly reduced compared to 2 flute.

Long tool life for copper milling by DLC coating.

Rake and relief angle are designed for copper milling and sharp cutting edge reduces burrs on milling surface.

Diameter tolerances have been significantly tightened compared to the conventional models.