| Copper, Aluminum | Raw Materials ~ 55HRC | >Hard Materials (40~65 HRC) |

Hard Materials (50~70 HRC) |

||

|---|---|---|---|---|---|

| Square | |||||

| Long Neck Square |

|||||

| Long Neck Radius |

VHGLRS

|

||||

| Ball | |||||

| Long Neck Ball |

For customers who are firstly trying carbide processing, we have created a "vital point" document.

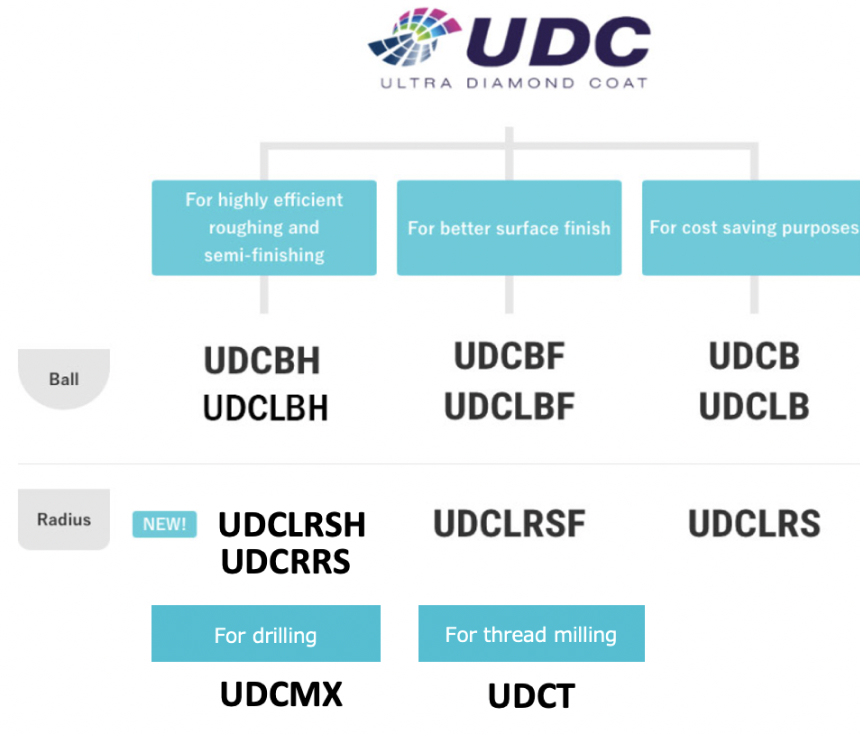

In 2012, we launched diamond coated end mills for processing cemented carbide. This series is applied UDC (Ultra Diamond Coating), which offers excellent hardness and durability by improving adhesion to cemented carbide and controlling fine particle composition, and literally 'cuts' cemented carbide stably with long tool life. Furthermore, the best-designed tool geometry for processing cemented carbide makes remarkable DEEP cutting possible and achieved highly efficient and accurate processing of cemented carbide.

UDC-Hseries is the long-awaited UDC 3rd generation series with an optimized cutting edge

treatment and improved diamond coating with respect to the “F series”.

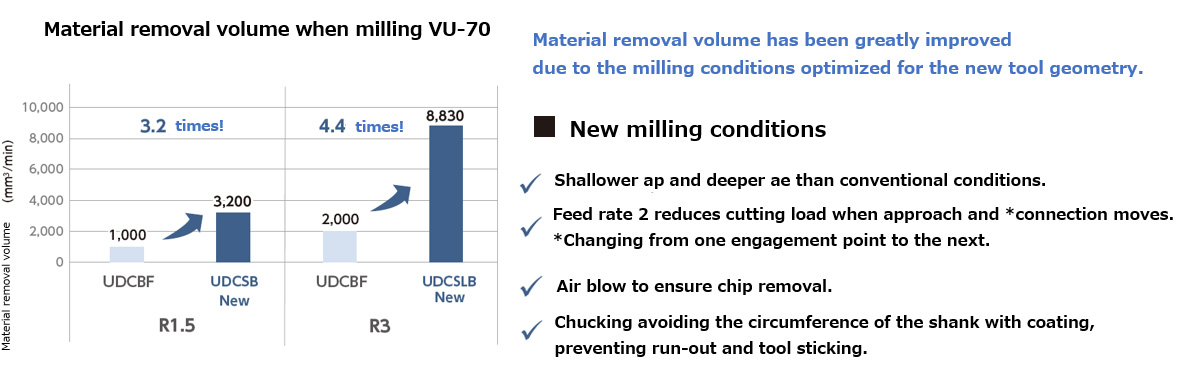

We can achieve high feed rates that up until now could not be dreamed of when imagining the direct milling of

cemented carbide. The material removal volume has also dramatically increased, and this is ideal for rough

processing to semi-finishing. By using it in conjunction with the previously launched “F” series, it is

possible to perform direct milling of cemented carbide with both high efficiency and high quality.

H

High-level Treatment!!

Unbelievable milling performance

High Speed!!

Mill at surprisingly high feed rate

High Material Removal Volume!!

Highly improved material removal volume

The key points

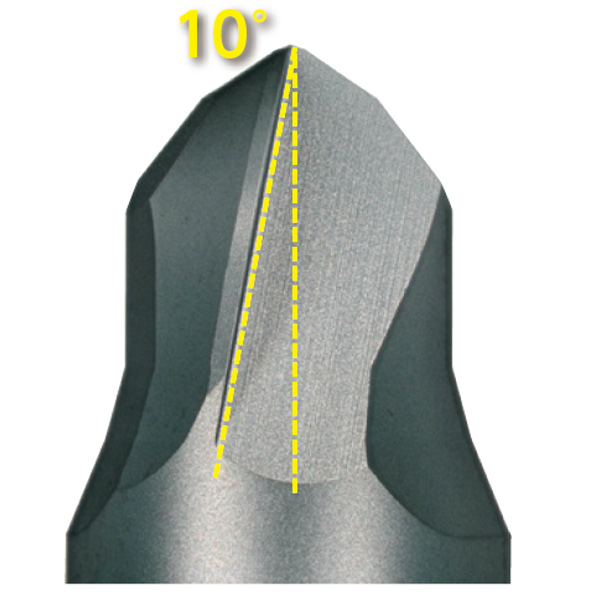

New generation edge treatment

minimize damage

Improved diamond coating

to enhance wear resistance

NEW! UDCBH

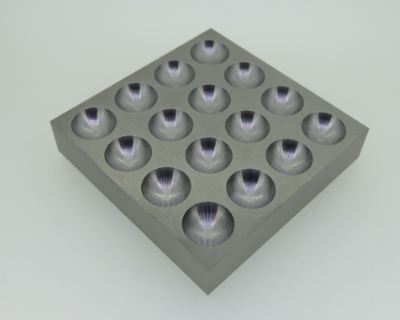

Work Size : 50 x 50 x 10 mm

Pocket Size : Top φ10 x Depth 3.5 mm

Material Romoval Volume : 160 mm3 / Pocket

Coolant : Air Blow

UDCBH shows maximum tool performance under high-speed conditions.

Tool life may shorten when used at the same feed rate as before.

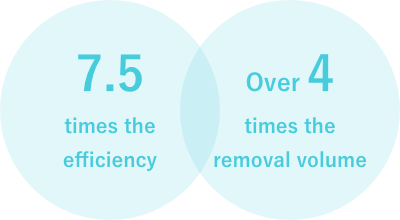

| NEW! UDCBH | UDCBF | |

| Milling Conditions | ||

| Spindle Speed (min-1) | 30,000 | 20,000 |

| Feed Rate (mm/min) | 1,500 | 200 |

| ap (mm) | 0.1 | |

| ae (mm) | 0.3 | |

| Milling Results | ||

| 1 side 16 pockets | 1 Tool Milling time 76分 | 4 Tool Mlling time 7 h 28 min |

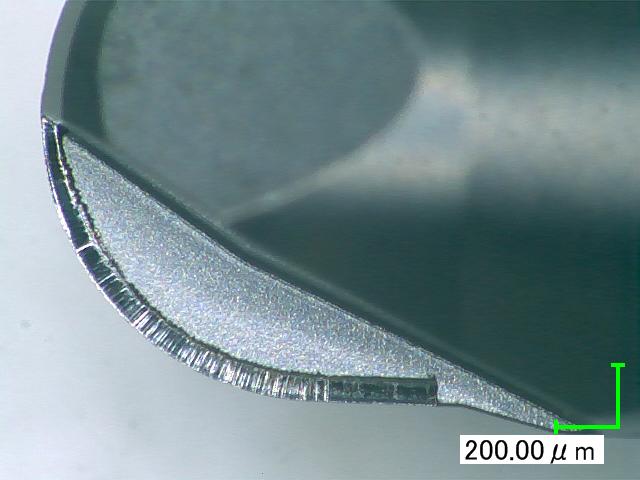

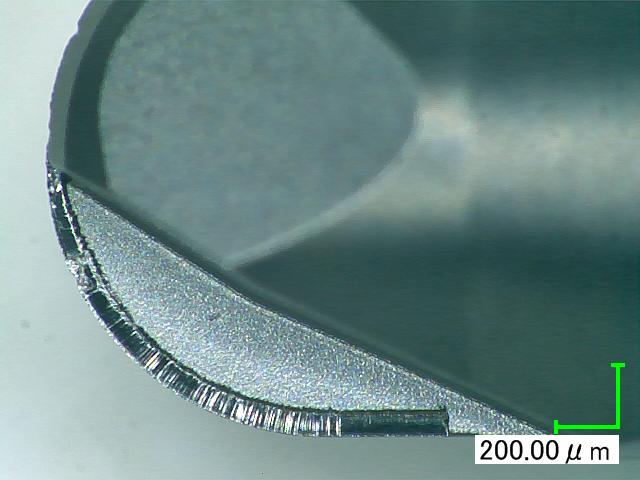

| Tool after milling 4 pockets |

|

|

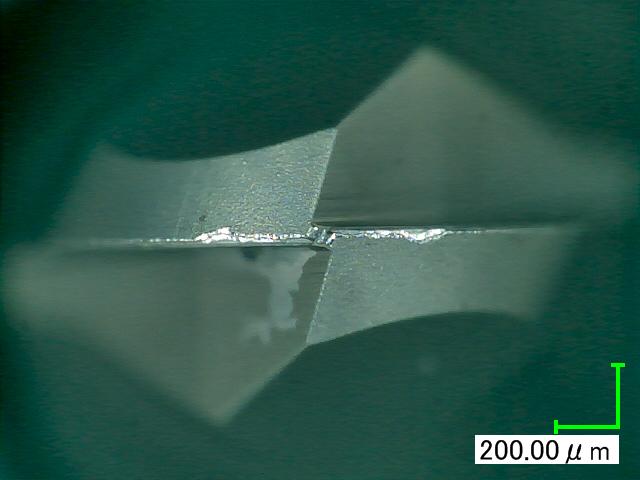

| Tool after milling 16 pockets |

|

- |

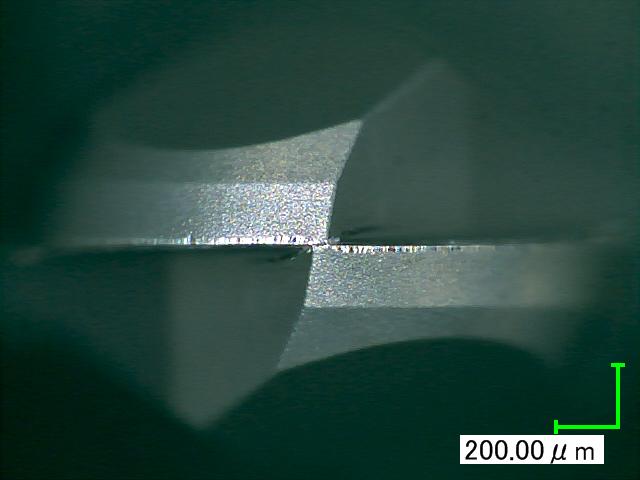

The sharpest cutting edge in the UDC series

The best choice for high quality milling surface

F

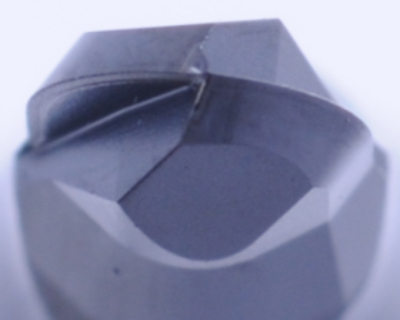

①UDC coating

Optimized coating for F series

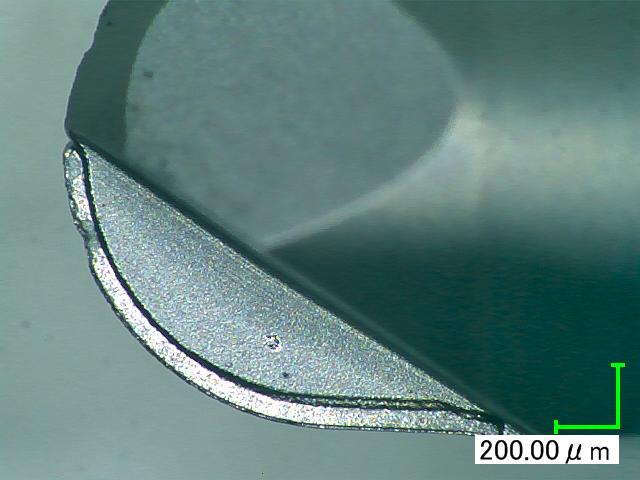

②Special treatment for a sharp edge

Minimized edge chipping and level gap

③Chip pocket designed on tool tip

Excellent surface finish

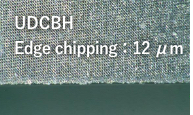

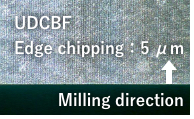

| Tool | UDCBH | UDCBF |

|---|---|---|

| Spindle Speed (min-1) | 30,000 | |

| Feed Rate (mm/min) | 750 | 250 |

| ap (mm) | 0.02 | |

| ae (mm) | 0.02 | |

| Coolant | Airblow | |

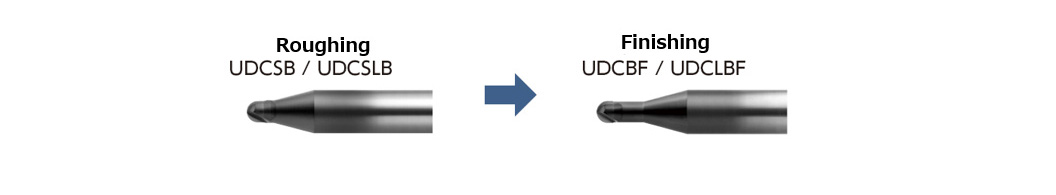

Improve efficiency and lower costs by using the right tool based on edge chipping requirements.

UDC series for milling of 87 HRA or lower hardness of cemented carbide

S

Angled flute design

Reduce damage during milling due to the angled flute design

UDC Coat : Outstanding adhesion to the tool

Outstanding adhesion to tool allows milling of tough materials

High material removal volume

Highly improved removal volume when milling

87HRA or lower hardness of cemented carbide material

Reduce cutting force and damage by angled flute design.

UDC-S is the solution

・Reduce the number of tools for direct milling.

・Reduce purchasing and machining costs for

electrode materials.

・Reduce polishing process and time.

・Improve the life of the cemented carbide mold.

UDCBF/UDCLBF are recommended for final finishing.

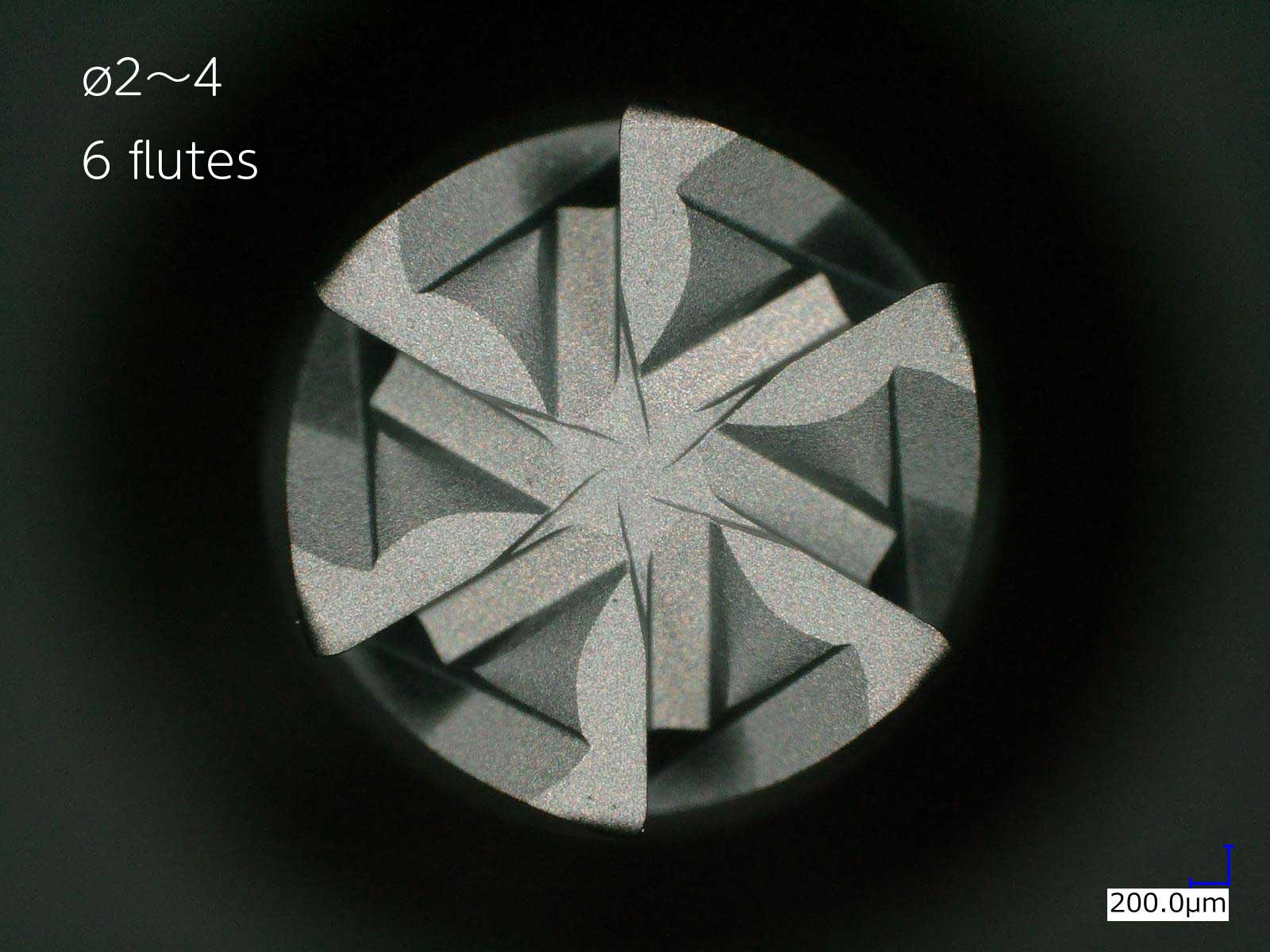

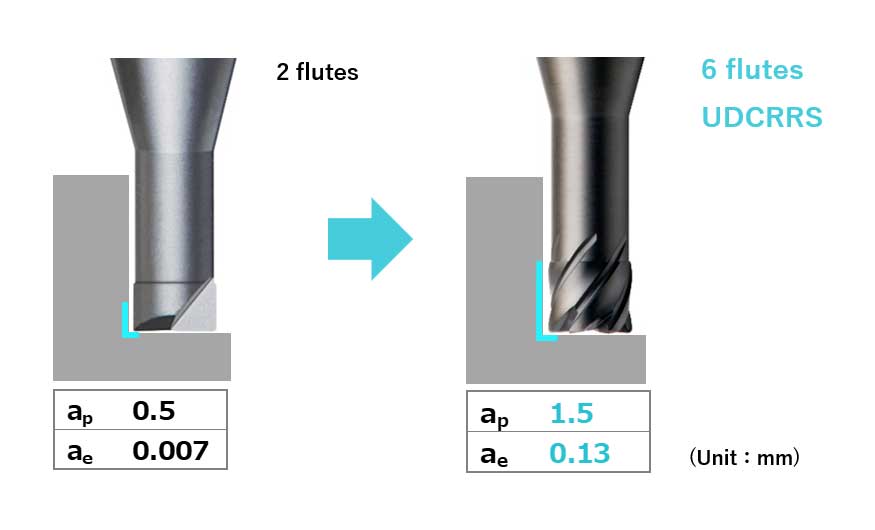

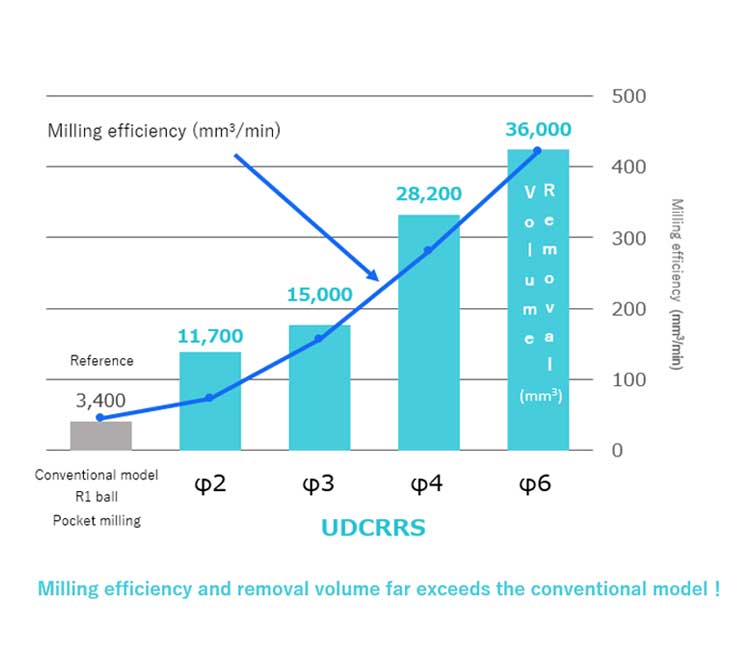

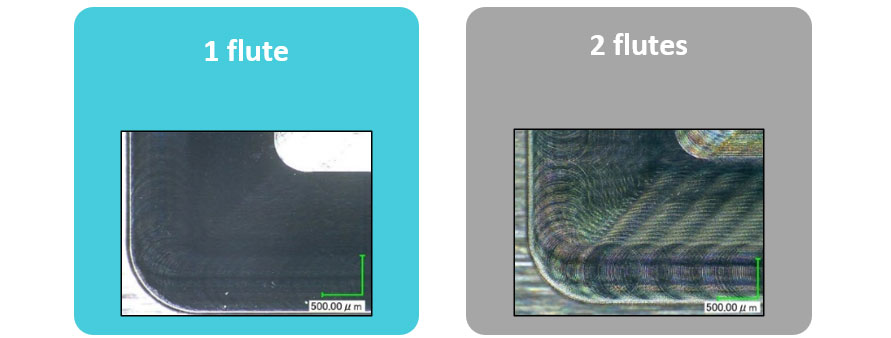

The 6 to 10 flutes and the 40 degree helix angle achieves low cutting resistance and offers deep cutting depth

milling!Compared to the 2 flute models, the efficiency has been dramatically increased!

This contributes to the reduction in cycle time.

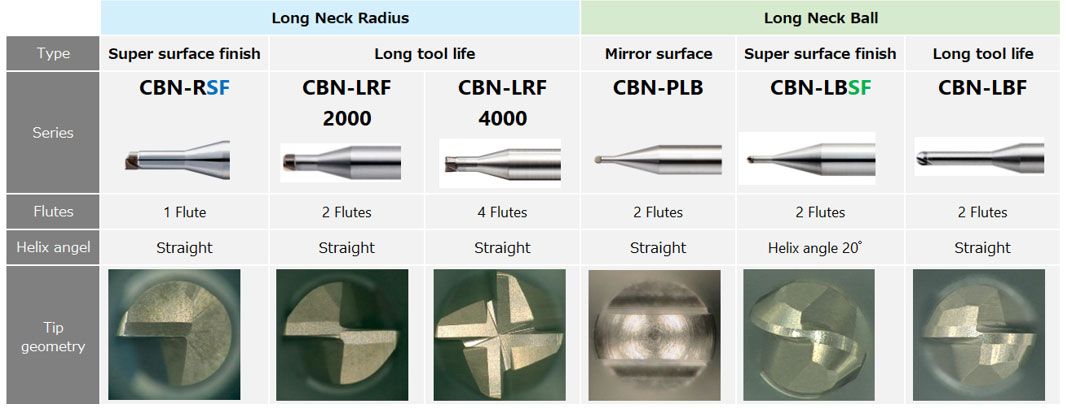

A new long neck ball CBN-PLB for super mirror surface processing has been added to the CBN series. The unique tip shape maximizes the burnishing effect and enables super mirror surface processing as opposed to the conventional series!The slot design that allows the coolant to reach the cutting edge improves the chip evacuation performance as well as preventing biting, which ensures the longevity of the mirror surface.

Long neck ball CBN-LBSF and long neck radius CBN-RSF series designed for super finishing can obtain a better

finished surface as opposed to conventional products due to the characteristic flute shape that achieves a

burnishing effect. Recommended for the finishing of high hardness materials that emphasize the finished

surface.

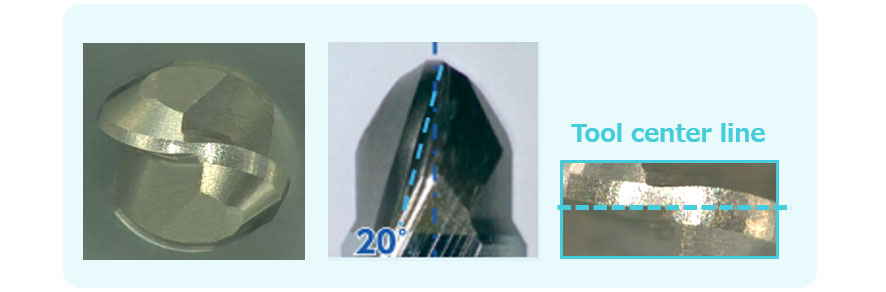

CBN-LBSF Features of tip shape

A cutting edge has been added to the tip of the tool (Zero peripheral speed point)

Suppresses tool damage and improves the finished surface!

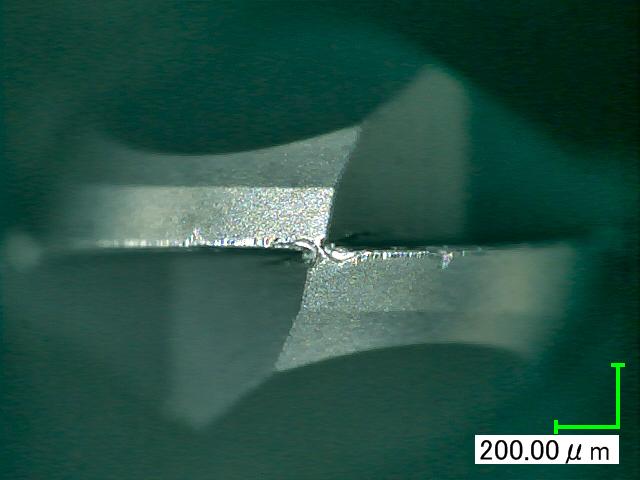

CBN-RSF Burnishing effect at the flute tip (ELMAX 60HRC)

Optimizing the width of the burnishing surface that rubs on the machined surface, will give a glossy surface and achieves a super surface finish!

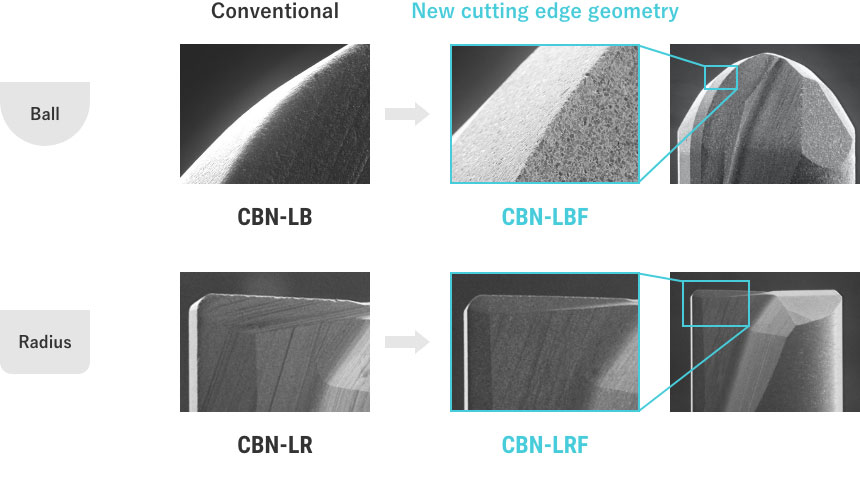

Optimized cBN material and improved cutting edge geometry for milling the ultra-hard materials offer high

precision milling and long tool life.

By excellent wear-resistance and chipping-resistance of the tool, outstanding surface roughness and

precision are maintained even under long cycle time. Recommended to use on finishing process for the

ultra-hard materials.

Improved sharp edge