シャンク3mm(h4公差)×全長38※mmのショートシャンク。

月産3,000万本のPCB工具の量産技術をエンドミルに展開し、よりお求めやすい価格を実現したシリーズ。

小径の高精度加工用に特化した設備により、高精度、高能率加工を実現。

(※VCBNシリーズは 全長35㎜となります)

| 銅・アルミ加工用 | 生材~55HRC加工用 | 高硬度材加工用 (40~65 HRC) |

高硬度材加工用 (50~70 HRC) |

||

|---|---|---|---|---|---|

| スクエア | |||||

| ロングネック スクエア |

|||||

| ロングネック ラジアス |

VHGLRS

|

||||

| ボール | |||||

| ロングネック ボール |

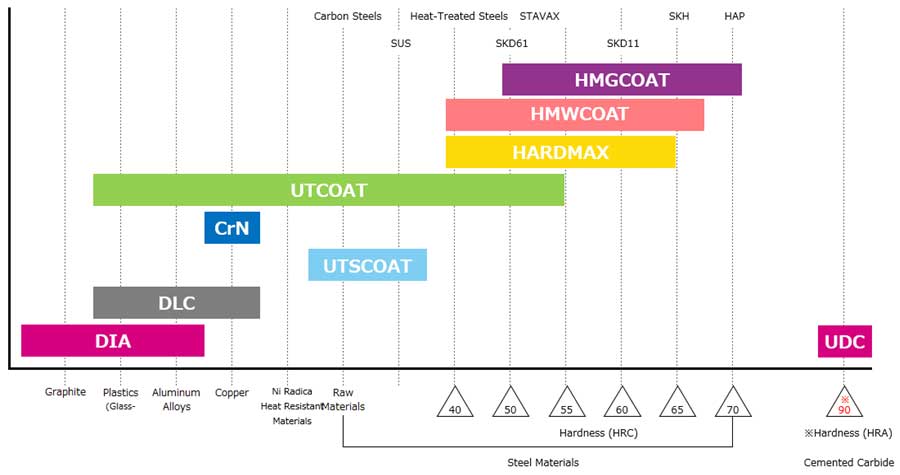

高硬度材加工時における耐摩耗性を極限まで高めたHMGCOATを採用したシリーズです。

焼入れ鋼、特に60HRC以上の焼入れ鋼において長寿命加工を実現します。

| ボール | ロングネック ボール |

ロングネック ラジアス |

|

|---|---|---|---|

| 2枚刃 |

HGB

|

- | |

| 4枚刃 | - | - | |

| 5枚刃 ~ 6枚刃 |

- | - |

HARDMAXは高硬度材加工時に求められる硬度と耐熱性を両立させたコーティングです。

特に40HRC以上の高硬度材の加工において性能を発揮するシリーズです。

UTCOATは潤滑性と靭性を高めたコーティングです。

表面が非常に滑らかで、摩擦係数も低く、切りくず排出性と耐摩耗性を高めました。

生材や靭性の高い被削材に適したシリーズです。

UDCはダイヤモンドコーティングの抜群の硬さに靭性を付与させた特殊ダイヤモンドコーティングです。

超硬母材とダイヤモンドコーティングの密着性も向上させることで、超硬合金や硬脆材で驚異的な切り込みでの加工を実現します。

非常に高い耐摩耗性を有するバインダレスPCDを使用し、シャープな切れ刃を形成することで超硬合金や硬脆材に対して、高精度・高品位の仕上げ加工を実現します。

高硬度材に適したCBN素材を採用し、高品位かつ高精度の仕上げ面が得られる刃形状を採用。

40HRC以上の高硬度材においてコーティング超硬工具よりも長い時間において安定した加工を実現します。

密着性・耐摩耗性に優れたダイヤモンドコーティングです。

グラファイト加工における長寿命を実現します。

| スクエア | ロングネック スクエア |

ロングネック ラジアス |

ボール | ロングネック ボール |

テーパネック ボール |

|

|---|---|---|---|---|---|---|

| 2枚刃 | - | |||||

| 4枚刃 | - | - | - |

※CGE、CGB2000、CGB4000シリーズはノンコートとなります。

CrNとDLCは高い潤滑性を有するコーティングです。

DLCは独自の技術で硬度と潤滑性を更に高めることで、電極の銅や銅タンで高品位かつ長寿命な加工を実現します。

UTSCOATは潤滑性と靭性を有するUTCOATに更に高潤滑層を付加し、耐溶着性を向上したコーティングです。

靭性の高い材料、特にステンレスの加工において性能を発揮します。

良好な切れ味と切りくず排出を有するアルミ加工専用工具です。

独自の技術で硬度と潤滑性を更に高めたDLCを付与することで、長寿命加工を実現します。

※CAS、AZSシリーズはノンコートとなります。

高靭性材に適したUTCOATシリーズの中でも、特に難削材に最適な刃形状を有するシリーズです。

良好な切れ味を有する樹脂加工専用工具です。

ロングネック、ロング全長など、樹脂加工に最適なシリーズです。