Union Tool believes that assessing and appropriately disclosing the risks and opportunities that climate change poses to business activities is essential for sustainable corporate growth and the creation of a sustainable society, and the company discloses such information in accordance with the TCFD framework. *1

*1TCFD: Task Force on Climate-related Financial Disclosures

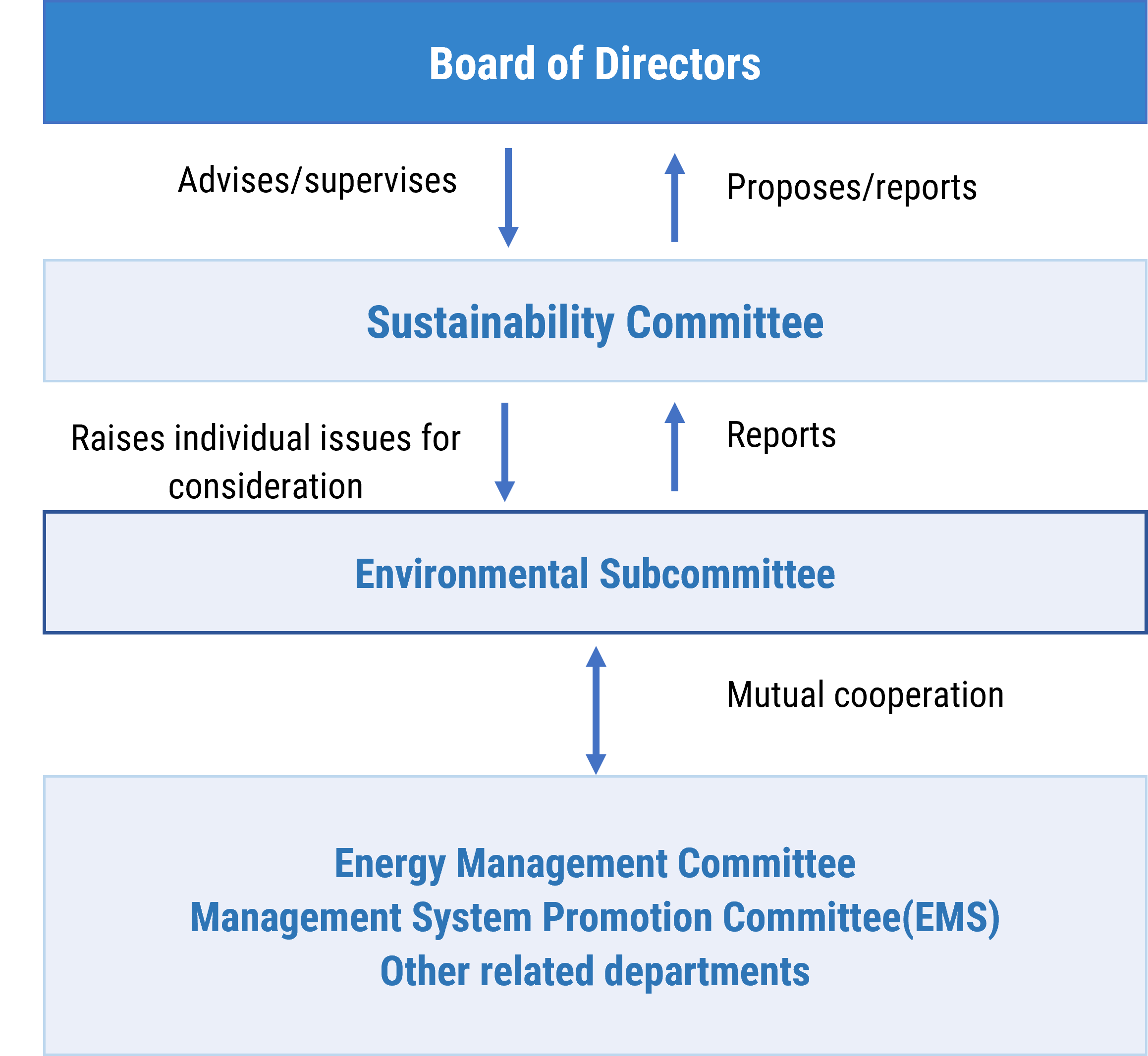

With the intention of contributing to the resolution of social sustainability issues in accordance with the Basic Sustainability Policy, Union Tool will continue to implement several company-wide initiatives in order to further intensify and increase the effectiveness of corporate activities. The company established the Sustainability Committee (hereinafter referred to as “the Committee”). The president and COO serves as the chairman of the Committee while the members are mainly directors and executive officers with a good understanding of each department and who have been appointed by the chairman. Reporting directly to the Board of Directors, the Committee revises basic policies, compiles and evaluates sustainability issues, and formulates different measures while issuing instructions related to their execution, supervising their implementation, reporting, and submitting proposals on the results to the Board of Directors. Additionally, the Environmental Subcommittee has been set up as a subordinate organization.

The Environmental Subcommittee analyzes and evaluates the impact (risks and opportunities) of future climate change on business activities and reviews it as appropriate. The details of such an analysis and evaluation are reported to the Committee and then used to develop initiatives addressing environmental issues in cooperation with related departments.

Figure 1: Organizational chart

Based on future climate change scenarios, Union Tool has identified risks and opportunities to approximately 2050 and has compiled a series of related countermeasures. The main scenarios referenced in this analysis are shown in the table below.

Table 1: Main reference scenarios

| Temperature increase | Transition scenarios | Physics scenarios |

| IEA*2 World Energy Outlook 2021 | IPCC*3 AR5,AR6 | |

| 4℃ | STEPS (Stated Policies Scenario) | RCP8.5 |

| 2℃ | SDS (Sustainable Development Scenario) | RCP2.6 |

Union Tool examined the PCB tools, which account for about 70% of the Group's sales, and analyzed the production and sales of three manufacturing subsidiaries in Japan and overseas.

Table 2: Climate-related risks for the company and related countermeasures

| Risk type | Generating factors | Expected financial impact on the Company | Relevance | Measures and implementation status | |

| Transition risk | Government policies /regulations |

Increasing cost of GHG emissions | The introduction of environmental taxes and similar measures will cause fossil fuel prices to rise leading to an increase in the cost of procuring energy. | Medium | ・Establish an Energy Management Committee to reduce power consumption and CO2 emissions through a variety of energy-saving measures. ・Promote the development of highly efficient in-house production equipment and update existing in-house infrastructure to energy-saving models. |

| The introduction of environmental taxes and similar measures will cause energy prices to rise leading to an increase in the cost of procuring raw materials. | High | ・Promote the development of eco-friendly products focusing on resource saving by means of extending tool life and original manufacturing technology. | |||

| Market | Changes in consumer behavior | Opportunities for selling products will decline because of the reluctance to buy products arising from greater awareness of energy saving and resource saving or from the lack of demand for final products caused by the extension of the upgrade cycle. | High | ・Increase cooperation with users and intensify surveys of market trends by specialized bodies in order to quickly develop products that meet the quality requirements of the next generation. ・Promote research and development of new products and production equipment with a view to enhancing quality. |

|

| Rising costs of raw materials | Following the growing demand for cobalt used for lithium-ion batteries in EVs and similar devices, the cost of procuring cobalt-containing cemented carbide will increase. | High | ・Promote the development of eco-friendly products focusing on resource saving by extending the life of extended tools and through original manufacturing technology. ・Promote the consideration of alternative suppliers and alternative materials. |

||

| Physical risk | Worsening conditions |

Increased severity and frequency of extreme weather events like cyclones and floods | Supply chain interruptions caused by floods and other natural disasters hinder the availability of raw materials and product shipments, resulting in a decrease in sales. | Low | ・Implement preventive measures against disasters in accordance with the Business Continuity Plan’s Basic Manual and ensure business continuity in the event of a disaster. ・Promote consideration of business continuity plans that includes suppliers and promote further strengthening of the entire Group’s production system. |

| Natural disasters such as floods cause damage to factories, generating recovery costs. | Low | ・Prepare for flood damage by creating a basic manual and prevent flood damage. ・Carried out the necessary action to prevent damage to production facilities by flooding in factories. |

|||

| Natural disasters such as floods cause damage to factories and stop manufacturing lines and product shipment, resulting in a decrease in sales. | High | ・Prepare for flood damage by creating a basic manual and prevent flood damage. ・Carried out the necessary action to prevent damage to production facilities by flooding in factories. |

|||

Table 3: Climate-related opportunities for the Company and corresponding measures

| Risk type | Generating factors | Expected financial impact on the Company | Relevance | Measures and implementation status |

| Increased resource efficiency |

Increased efficiency of production and distribution processes | An increase in the use of recycled materials as part of efforts aimed at resource recycling will drive down the cost of raw materials. | Low | ・Arrange for the retrieval of PCB tools and drill cases and actively promote reuse. |

| Resilience | Enhanced abilities to respond to abnormal weather like cyclones and floods | The formulation and implementation of business continuity plans improve resilience in the stable supply of products and raise consumer trust, leading to increased sales. | Low | ・Implement preventive measures against disasters in accordance with the Business Continuity Plan’s Basic Manual and ensure business continuity in the event of a disaster. ・Carried out the necessary action to prevent damage to production facilities by flooding in factories. ・Promote consideration of business continuity plans that includes suppliers and promote further strengthening of the entire Group’s production system |

| Market | Access to new markets | Sales will increase by expanding demand due to the spread of automation and data technology, such as smart cities, and satisfying the quality requirements for our products, which are becoming more sophisticated. | High | ・Increase cooperation with users and intensify surveys of market trends by specialized bodies in order to quickly develop products that meet the quality requirements of the next generation. ・Promote research and development of new products and production equipment with a view to enhancing quality. |

| Increasing production capacity and optimizing product mixes to cope with the increased demand for products resulting from the establishment of remote work and the shift to EVs will drive sales up. | Medium | ・ Manage production across the entire Group by holding regular global production meetings. ・Develop and invest in next-generation equipment in order to expand production capacity in accordance with future forecasts based on sales information and external specialized bodies. |

Union Tool first identified the possible effects of manufacturing and selling PCB tools, as well as of surrounding factors like policies, energy, markets, stakeholders, and environment. We then envisioned their financial impact in terms of 2°C and 4°C scenarios and picked out the most important factors by weighing each risk and opportunity. In response to the identified risks and opportunities, the Committee formulated measures to avoid and mitigate risks, initiated opportunities, made proposals, and reported to the Board of Directors and was subject to supervision. Additionally, as part of the PDCA activities, Union Tool monitors the implementation status of related measures and their effects.

As one of our initiatives, Union Tool considered flood prevention measures for our Nagaoka factory. In 2024, we carried out construction work to prevent flooding inside the factory.

As indicators for evaluating and managing the environmental impact of all corporate activities, Union Tool uses the amount of CO₂ emitted during production and the service life of the product. Additionally, the company assesses and monitors the environmental load generated by business activities from input to output and strives to carry out activities to effectively reduce the environmental load by promoting energy saving, recycling, and resource saving.

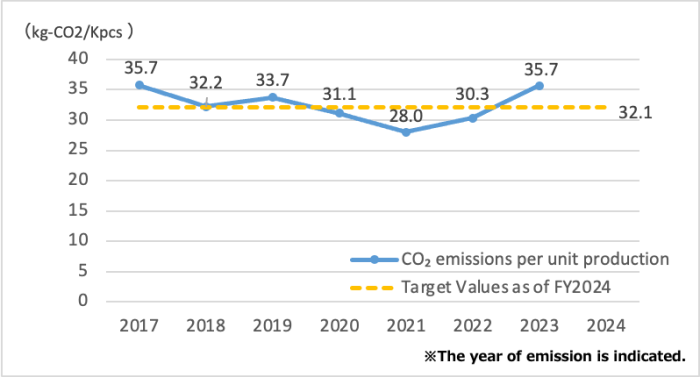

As for reducing CO₂ emissions, Union Tool set the target of reducing CO₂ emissions per unit production by 5% compared to FY2019 (five-year plan) as a way to conserve energy, which is a priority issue, and the entire company is working together to achieve this goal. The actual values of CO₂ emissions and the details of related initiatives are indicated below.

Table 4: Initiatives for FY2024(Nagaoka Factory)

| Item | Details | FY2024 targets |

| Energy saving | Improving CO₂ emissions per unit production*4 by 5% compared to FY2019 by FY2024 | Reducing the equivalent to 1% of FY2023 energy-derived CO₂ emissions*5 through corrective measures. |

| Resource saving | Promoting the development of environmentally friendly products | Developing high-performance tools |

| Resource saving Recycling | Promoting initiatives informed with plastic-free and carbon-free awareness | Reducing CO₂ emissions per unit production by 10% compared to FY2023 by increasing the use of PCB tool cases recycled or with low environmental impact |

Fig. 2: CO₂ emissions per unit production(Nagaoka Factory)